Experience a more comfortable sleep through the measurement of thermal effusivity.

By measuring thermal effusivity with the TPS-EFF, you can determine the best materials to use that ensure a good night’s sleep. Use effusivity to help create sleep products that transfer heat slower or quicker, depending on the desired situation.

Applications of Thermal Effusivity

The TPS-EFF uses a single-sided 30 mm diameter TPS sensor and short test times, to ensure one-dimensional heat flow. During the measurement, the sensor is heated using a constant current source, while the temperature rise of the sample is simultaneously recorded with time, by monitoring the change in electrical resistance of the wire spiral. The slope of temperature against a special function of time, is used to calculate the thermal effusivity of the material. For materials of relatively high effusivity, the slope will be lower, than materials of low effusivity.

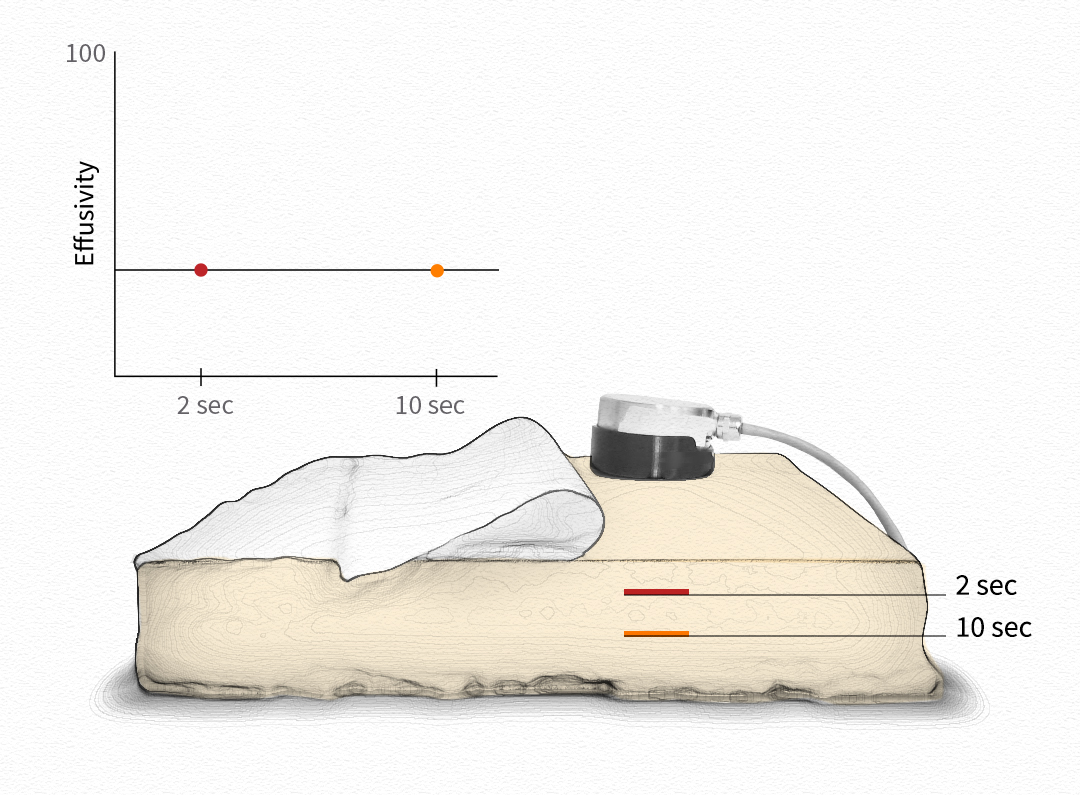

Thermal Effusivity of Mattress Foam

To measure the feeling of thermal effusivity, a mattress foam was measured at touch time of 2 and 10 seconds. As the sample is monolithic, the feeling of thermal effusivity is the same for both touch times, regardless of penetration depth.

| Sample Material | Mattress Foam |

|---|---|

| Sample Thickness | 50 mm |

| Method | Thermtest TPS-EFF |

| Measured results | 2 seconds: 36 W√s/m2K 10 seconds: 38 W√s/m2K |

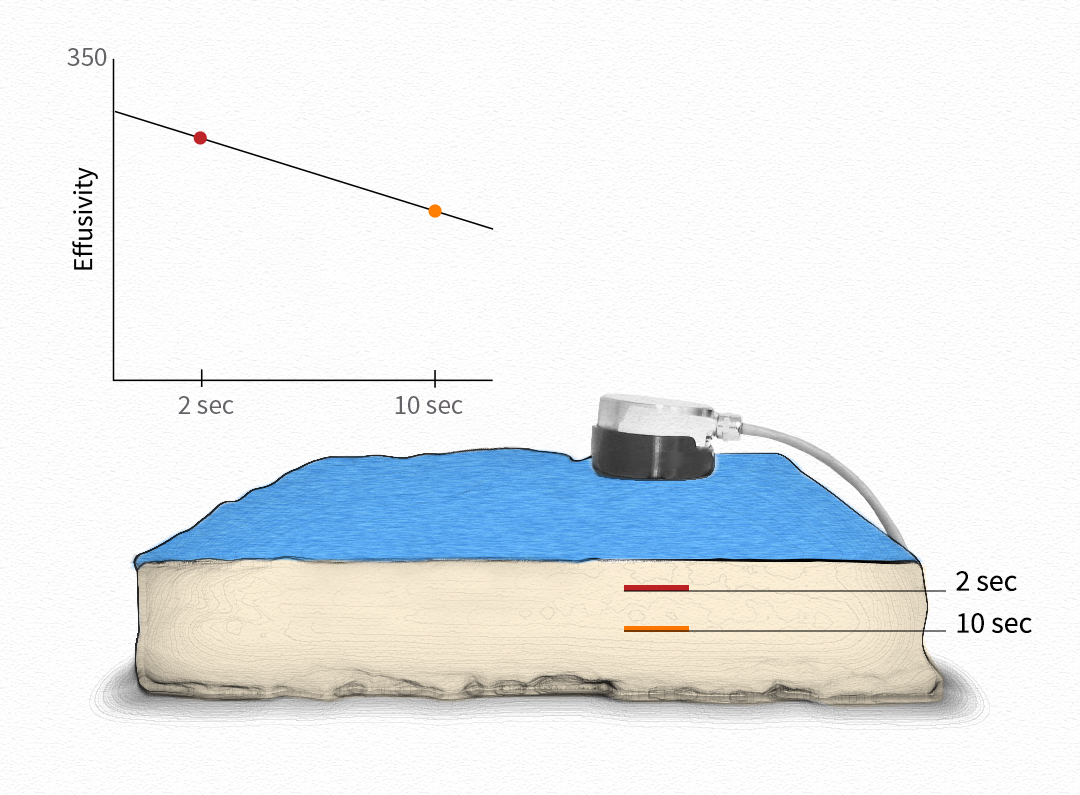

Thermal effusivity of Proprietary Effusive Textile over Mattress Foam

The 2 second thermal effusivity is higher due the vinyl textile, during the 10 second measured heat penetrate deeper into the sample, further decreasing the thermal effusivity.

| Sample Material | Proprietary Thermally Effusive Textile over Mattress Foam |

|---|---|

| Sample Thickness | 0.35 + 50 mm |

| Method | Thermtest TPS-EFF |

| Measured results | 2 seconds: 214 W√s/m2K 10 seconds: 125 W√s/m2K |

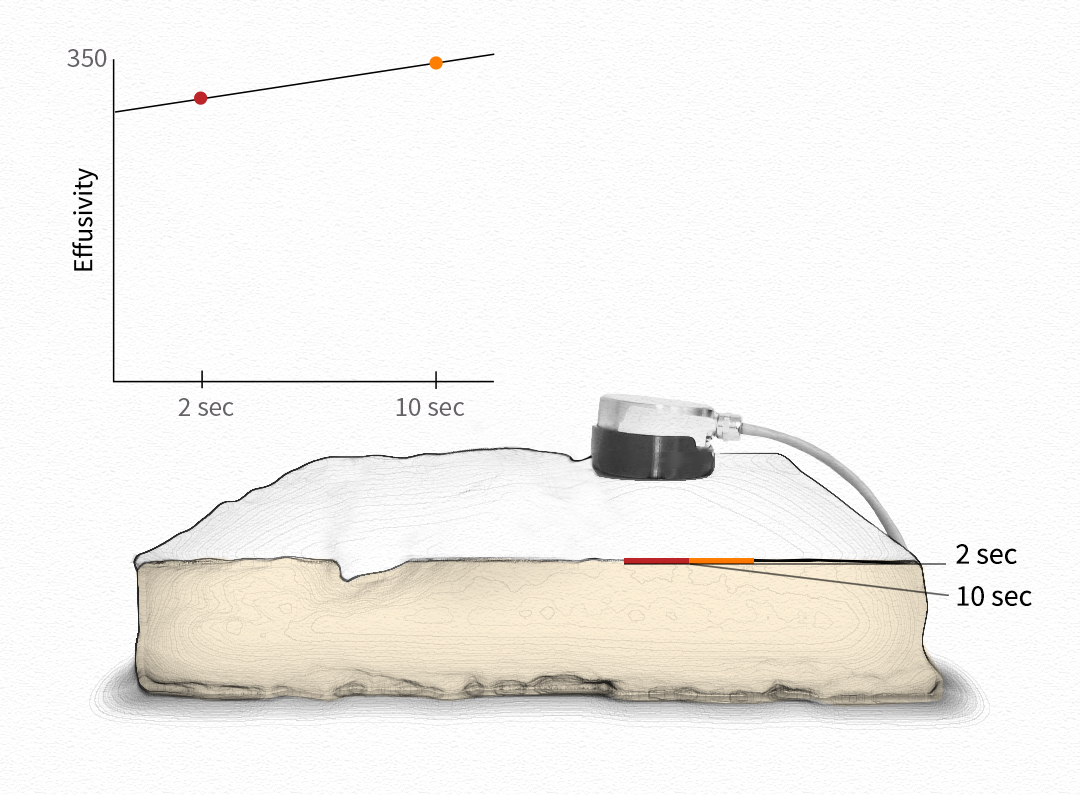

Thermal effusivity of Phase Change Material (PCM) Textile + Mattress Foam

Both the 2 and 10 second thermal effusivity results are higher as the heat from sensor is absorbed into the PCM during the cooling reaction.

| Sample Material | PCM Over Mattress Foam |

|---|---|

| Sample Thickness | 0.7 + 50 mm |

| Method | Thermtest TPS-EFF |

| Measured results | 2 seconds: 249 W√s/m2K 10 seconds: 342 W√s/m2K |